Case background

Jiangsu SUMEC Group Corporation, an important member of SINOMACH Group, founded its first garment factory in 2001. So far, SUMEC's textile and garment export business has been in the forefront of China, with products covering cotton and down jackets, outdoor sportswear, knitted garments, children's wear and so on.

In 2022, SUMEC Chuangjin apparel old factory started energy-saving renovation and upgrading, while the new factory in Liuhe started preparation. After comprehensive consideration of brand, quality, energy saving and other aspects, SUMEC chose Hemway equipment.

Solution

After the two sides contacted and clarified the specific needs, Hemway customized two different solutions for Chuangjin's new and old factories.

For renovation of the old factory, the original equipment was replaced with the Hemway M12 smart steam generator. The M12 with a power of 12kW can operate two irons at the same time, which can greatly improve the efficiency and speed of ironing work.

The new factory in Liuhe, uses the T120D intelligent quiet ironing table with strong moisture extraction and wind suction function, together with M5 intelligent steam generator with the two-speed power adjustable as a combination of high-efficiency ironing.

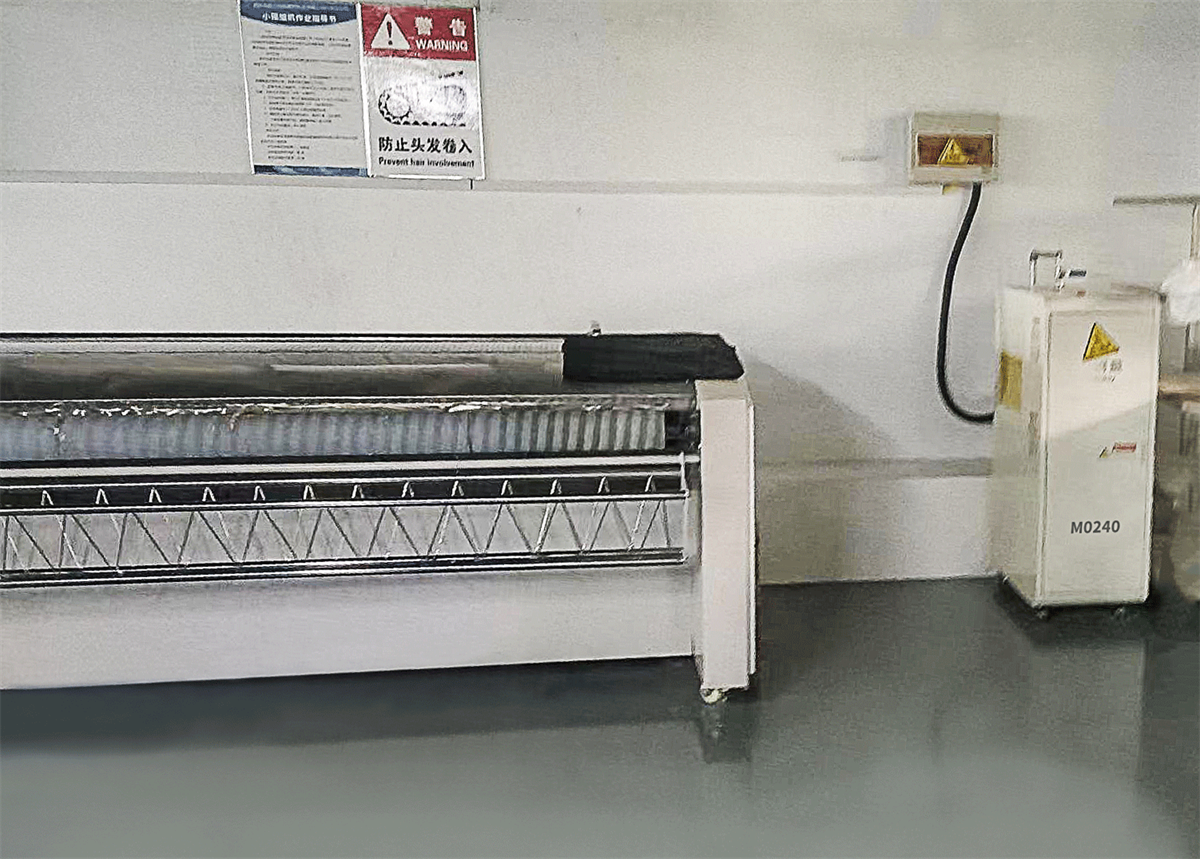

For the pre-shrinking process, factory use M0240 steam generator with 24kW power to meet the demand for high-quality steam in the pre-shrinking machine.

After using Hemway equipment, the excellent ironing effect and stable high-quality steam output have effectively guaranteed the production efficiency of the ironing workshops of the two factories, greatly reduced electricity costs, and improved overall benefits.

At present, Hemway's energy-saving steam overall solutions and product services have been widely used in fields other than the garment ironing industry, such as washing, printing and dyeing, automobile manufacturing, brewing, food processing, chemical industry, etc.

In the future, Hemway will continue to be committed to providing more efficient, environmentally friendly, and competitive energy-saving steam solutions, as well as customized automation products and services, to help more companies achieve the goals of cost reduction, efficiency improvement, and sustainable development.